Magnetic Polishing Machine Metal Finishing Machine Metal Parts Surface Polishing Machine Vibratory T

Manufacturer guarantee

1. Comprehensive quality control in the parts procurement process, all parts are from well-known brands

2. All machines can trace production batches to facilitate quality control and after-sales.

3. It is tested at all levels before shipment to ensure that there are no problems when the machine arrives.

Machine application

Suitable for grinding various irregular-shaped workpieces. Bore. The main scope of application is inside pipes, dead corners, cracks, etc.

Products include CNC automotive lathe parts, precious springs, zinc spring parts, aluminum die castings, and aerospace. Medical parts, precious die-cast parts, mobile phones, laptops, camera parts, communication parts, fashion accessories. Handicraft parts, precious screws and bolts, hardware parts, mold parts, glasses parts, instrument parts, etc.

Machine application:

Highly efficient, only takes 5-15 minutes (depending on material) magnetic polishing

Brief description: 1. The grinding speed is

Fast speed, average grinding time is about 5 minutes to 15 minutes, double machining groove workpiece replacement

It is fast and the grinding parts can be replaced while the machine is running.

2. Simple operation, absolutely safe, one person can operate multiple machines

3. Low cost, the semi-permanent grinding material uses stainless steel needles, and the consumption is extremely low.

Polishing fluid is the only consumable item

4. After the grinding is completed, the workpiece is easy to handle, and the workpiece and the stainless steel needle can be easily separated through the screen, screen cylinder, electromagnetic force or separator. Stainless steel needles are available in diameters ranging from 0.2-5MM to 1.2-10MM.

Machine advantages:

1. Multiple sets of abrasive belts, chamfering and polishing without dead ends;

2. The grinding precision is high, and you can choose to retain or remove the oxide layer of the workpiece;

3. The driving roller has a diameter of 240mm, a large contact area, good deburring effect and high efficiency;

4. For deformed boards and laser cutting boards, there is no problem that only the highest point can be polished;

5. The abrasive belt is automatically guided by CNC control, making the operation simple and precise;

6. Small parts are not a problem, as long as the width is greater than the height, they can be polished;

7. PLC full computer touch screen control, high precision, easy to operate;

8. Fast and efficient, one piece of equipment can support 20 people

9. Equipped with a high-power and low-energy consumption motor, it has strong power, strong sanding force and sufficient polishing.

10. The whole machine has a solid structure and is made of thick-walled welded formed steel.

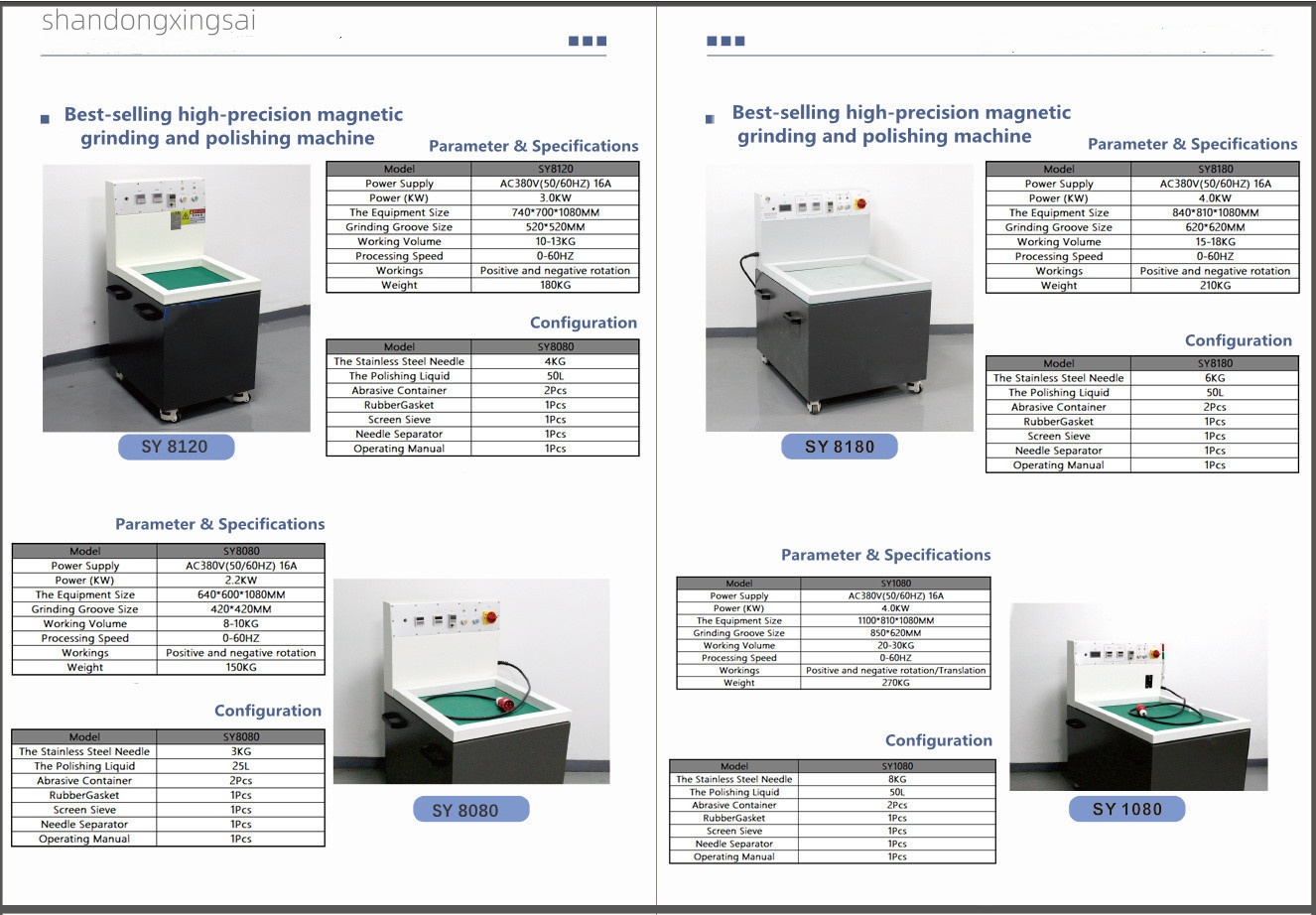

Model | Processing Weight | Groove Size | Power | Machine Size |

8080 | 1-30KG | 1100*600MM | 4KW | 1200*750*1150MM |

8120 | 1-60KG | 1800*600MM | 4*2KW | 1900*750*1150MM |

8180 | 1-80KG | 2500*600MM | 4*3KW | 2600*750*1150MM |

1080 | 1-100KG | 3100*600MM | 4*4KW | 3200*750*1150MM |