Semi automatic laser cutting parts manual metal sheet surface deburring grinding machine

Manufacturer guarantee

1. Comprehensive quality control in the parts procurement process, all parts are from well-known brands

2. All machines can trace production batches to facilitate quality control and after-sales.

3. It is tested at all levels before shipment to ensure that there are no problems when the machine arrives.

Machine features

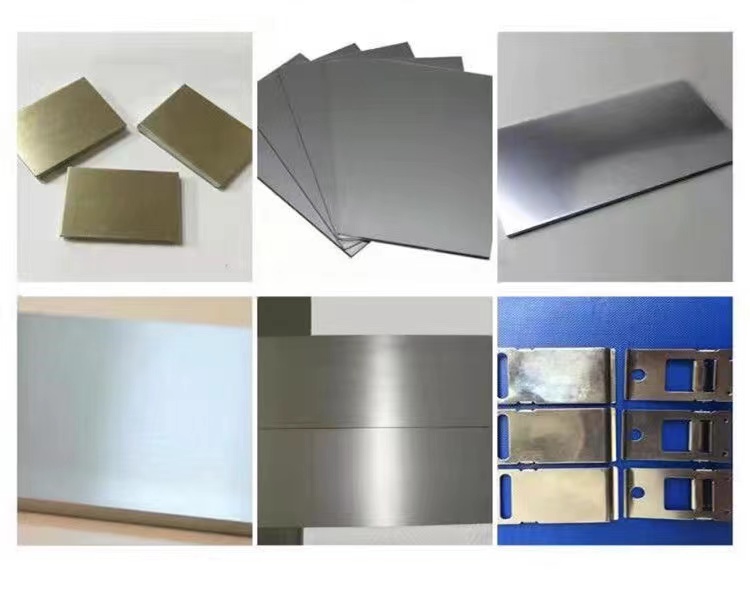

This model consists of a workbench and a mechanical polishing arm, and is suitable for surface polishing, slag removal, and deburring of small batches of metal plates.

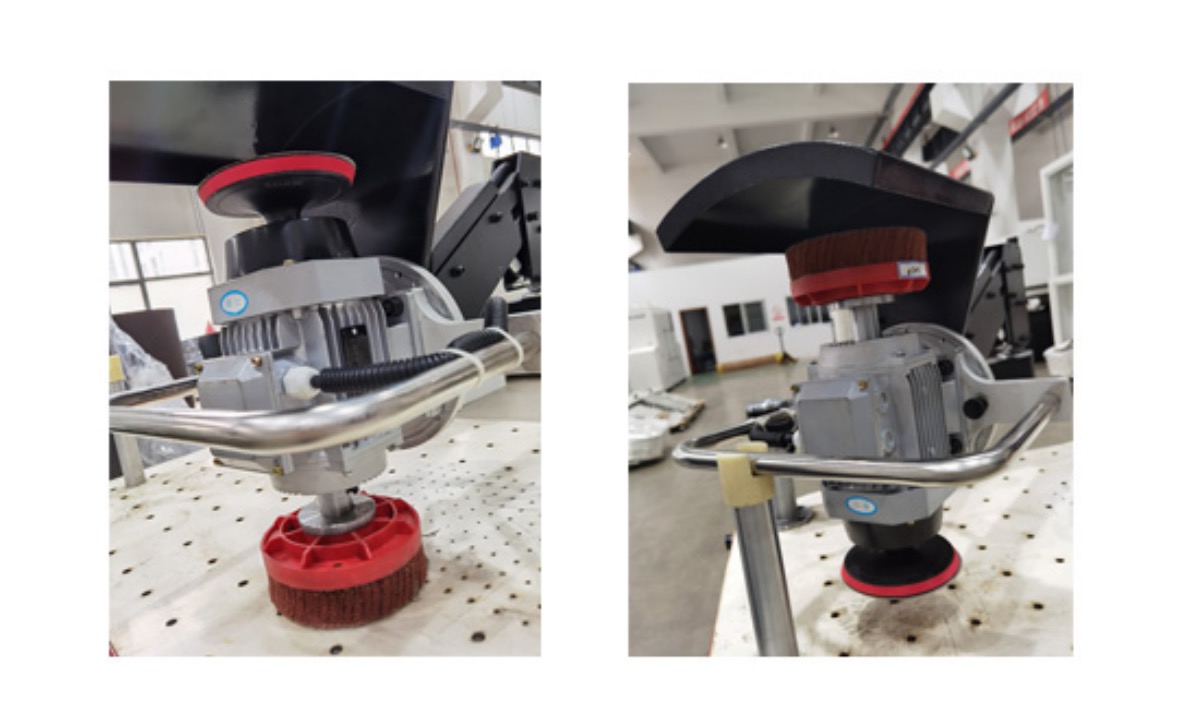

The machine is very easy to use and only requires manual pressure to achieve the required grinding force. The self-controlled vacuum adsorption workbench adopts vacuum adsorption for automatic distribution. The workpiece only needs to be placed flat on the workbench and can be ground without any clamping. It is efficient and safe. Can be selected according to actual workpiece. Different disc brushes can achieve the desired effect. The machine has a built-in dust collection function that automatically absorbs the wear debris generated when grinding workpieces to protect workers' health. The factory is clean and tidy. One power unit is equipped with two grinding heads, which can be quickly replaced by just rotating 180°, which is efficient, convenient, safe and energy-saving.

Machine application

Used to remove burrs, flash, fillets and chamfers from workpieces in stamping, laser, plasma, flame cutting, machining and other processes. The contact roller is mainly used for pretreatment of large horizontal burrs and surface drawing of the entire plate; 2 sets of brush disks rotate in both directions to ensure continuous and uniform polishing effect. Efficient and clean processing characteristics, suitable for workpieces to enter the next process of edge wrapping, surface spraying, welding and other processes. It solves the problems of low workpiece grinding efficiency and inconsistent grinding caused by manual grinding.

Stable 180 degree rotating axis Removable tray for easy replacement of sanding pads Deburring machine

1. Suitable for surface polishing, slag removal, deburring, etc. of small batches of metal sheets

2. There are two machine heads that can be installed with various types of work equipment.

3. Automatic vacuum adsorption table, automatically distributes vacuum suction, efficient and safe

4. Different brushes can be selected according to the actual workpiece to achieve the ideal effect.

5. With dust removal function.

Size Of Vacuum Adsorption Platform | 300*300mm |

Upper Platform Workpiece | 1000*750mm |

No Platform Artifacts | 1400*1400mm |

Cantilever Operating Range | 1400mm*360° |

Process Workpiece Thickness Range | 1-150mm |

Brush Size | φ162mm |

Sand Size | φ150mm |

Grinding Head Power | 0.75kw |

Grinding Head Quantity | 2pcs |

Vacuum Air Volume | 1000m³/h |

Total Power | 3.86kw |

Size | 1250*750*1500mm |